“India’s electronics sector stands at a pivotal juncture, while domestic demand, assembly capacity, and production-linked incentives have driven rapid growth, export performance continues to lag due to structural gaps, cost disadvantages, and fragmented ecosystem development,” the Aayog said in the sixth edition of its commentary publication ‘Trade Watch Quarterly’.

NITI recommended that the government rationalise input tariffs, correct inverted duty structures, and address logistics inefficiencies to narrow the 10-18 per cent cost gap vis-a-vis global competitors.

In its analysis, the think tank found that India faces a 10-14 per cent cost disadvantage in assembly and 14-18 per cent in components versus China and Vietnam. Moreover, high capital costs and logistics add to competitiveness gaps.

It also recommended the introduction of VAT/GST refunds or rebates on imported raw materials to support battery and critical component manufacturing and incentivise domestic capacity creation, along with integration of capex subsidies, tax incentives, and research and development (R&D) support with labour and utility cost measures to enhance overall manufacturing competitiveness.

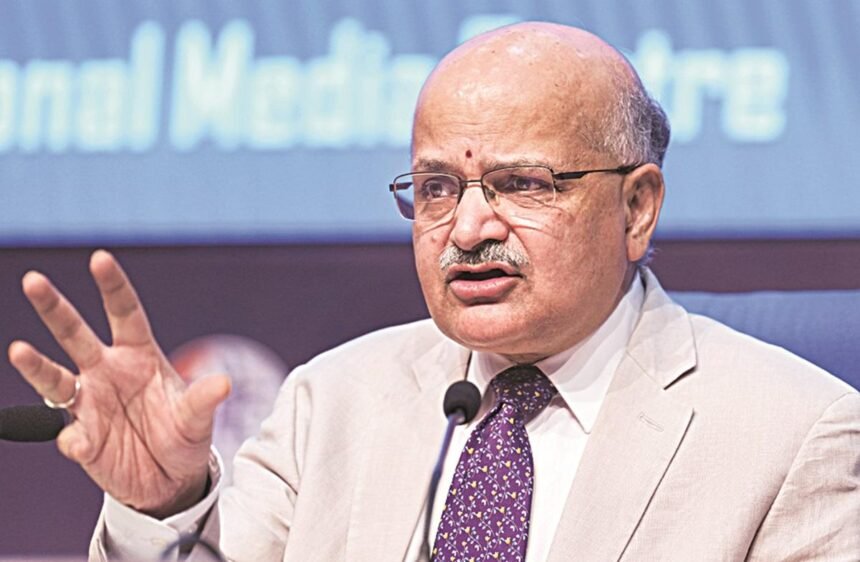

According to NITI Aayog Vice Chairman Suman Bery, India needs intelligent policymaking in the ‘Buy vs Make’ strategy when it comes to the export value chain, which aims to navigate complex geopolitical developments with realistic domestic ambitions.

“If we are very dependent on manufacturing inputs, in a world with weaponised trade, it is a source of vulnerability,” said Bery, adding that there needs to be a focus on quality at the same time.

According to NITI Aayog member Arvind Virmani, India’s is the 4th largest manufacturing power in the world, but the 15th or 20th largest exporting power.

The Aayog also recommended that the government reorient incentive frameworks to explicitly reward production of critical components, sustained R&D investment, and end-to-end supply-chain integration.

It also called for developing electronics manufacturing clusters with shared testing, certification and reliability labs (EMC, safety, environmental testing), and other necessary facilities to reduce compliance costs and shorten product cycles.

The need to expand trade would also have to go hand in hand with India’s ambitions on employment and gender inclusiveness in the labour force, said Bery.

It recommended targeted skilling programs in chip design, embedded software, system integration, and advanced product testing to meet global standards and support the $ 500 billion electronics manufacturing target by 2029-2030.